Dimensional Weighing

Cubing Systems

Get the Most Accurate Measurements with Advanced Cubing Systems

Efficient package handling can define the success of your facility’s operations. However, you can quickly fall behind if inaccurate package measurements or outdated systems hinder your shipping and storage processes. It’s time for an upgrade! You can streamline your operations with high-quality cubing systems, ensuring precise package dimensions for optimized distribution and storage. At Dimensional Weighing, we offer cutting-edge solutions that cater to all your cubing needs, backed by years of expertise.

What is Cubing?

Cubing, also known as package dimensioning, refers to determining a package’s cubic volume by accurately measuring its length, width, and height. These measurements are essential for calculating an object’s dimensional (DIM) weight, a key component in logistics and shipping cost determination. By leveraging automated cubing systems, facilities can promise storage efficiency and cost-effective shipping practices.

Innovative Cubing for Every Need

At Dimensional Weighing, we understand the importance of having reliable cubing systems geared toward the requirements of your facility. That’s why we offer versatile solutions, including:

- Static Dimensioning Systems – Ideal for smaller packages, our precise static cubing and weighing systems are perfect for processing inventory in warehouse operations or shipping. These compact solutions provide accurate measurements of smaller, lightweight parcels.

- Pallet and Large Freight Scanners – For larger goods or awkwardly shaped items, our pallet and freight scanners ensure the effortless cubing of oversized packages. These systems are well-suited for truckload management and warehouse optimization.

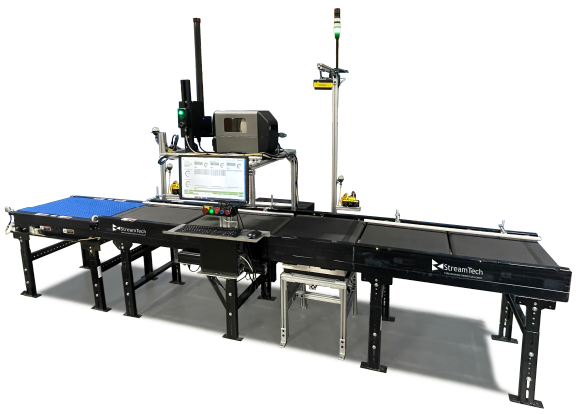

- Dynamic/ In-Motion Cubing Systems – The cubing process is all about automation! With our dynamic systems that integrate with your conveyor belt setup, there’s no wasting time with manual measurements. These in-motion cubing scales and scanners capture real-time dimensions of parcels as they move on the conveyor line, maximizing efficiency.

What are the Advantages of Utilizing Cubing Systems?

Integrating advanced cubing systems into your operations ought to be the first thing you do when planning for shipping and logistics operations. Cubing systems come with numerous benefits, including:

- Efficiency at Scale – Minimize labor-intensive processes such as manual measuring and weighing. Automated cubing scanners allow you to process more shipments faster while reducing bottlenecks in your facility.

- Pinpoint Accuracy – Human error can lead to costly miscalculations. Our sophisticated systems always provide precise measurements, reducing the risk of overpaying shipping costs while optimizing space utilization.

- Cost Savings – Accurate dimensional calculations help facilities avoid additional shipping fees for inaccurate measurements. Additionally, optimized load planning can significantly reduce transportation and storage expenses.

- Seamless System Integration – Our cubing scanners can easily connect to your current warehouse management systems, ensuring accurate data collection and real-time updates without disrupting existing workflows.

- Real-Time Reporting for Quick Decisions – Capture and access real-time parcel data for faster decision-making. This streamlined approach leads to increased productivity and improved service levels.

Get the Right Cubing System for Your Facility

Upgrading to Dimensional Weighing’s state-of-the-art cubing systems guarantees smooth operations and precise package handling. From small businesses to large warehouse operations, our solutions are designed to support your facility’s growth and adaptability. Contact Dimensional Weighing today to learn more about how our cubing systems can enhance your logistics and shipping processes. Call us at 309-698-1500 or request a quote through our website. We provide our products for clients across the United States.