Dimensional Weighing

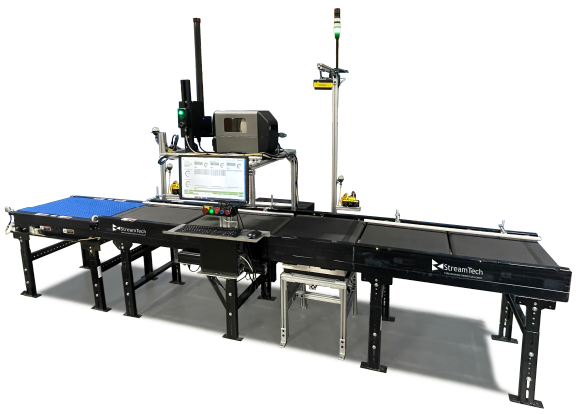

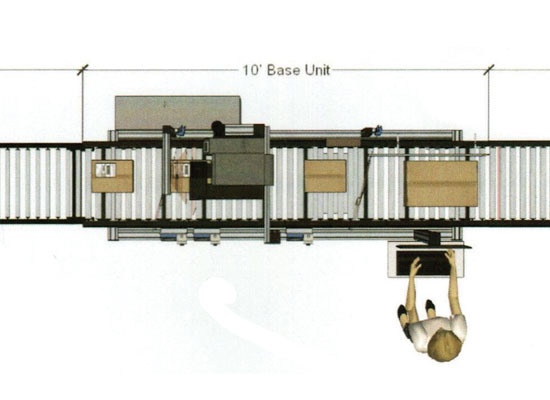

Sprinter Shipping System

Reduce your labor costs, slash output bottlenecks, improve accuracy, and beat carrier cutoff times with automatic shipping and manifesting at a reasonable cost, with quick implementation based on a pre-engineered approach. The Sprinter is capable of scanning, weighing, dimensioning, print and applying labels and verifying. This is a robot that works without errors, breaks or overtime, enabling you to efficiently scale both for regular days as well as seasonal peaks without cost & headaches of more staff. Built using off-the-shelf parts and components familiar to most warehouse maintenance staff, the Sprinter is affordable to maintain and support for years to come.

• Reduce or re-allocate manual labor

• Eliminate the need for multiple shipping stations dedicated by carrier

• Eliminate data entry errors

• Increase throughput while maintaining your service level

• Automate rate-shopping, address verification and proof of delivery (paired with multi-carrier system)

Sprinter Automated Shipping System Features

Induction Scan

The first step in most processes is identifying what you are working with. The Sprinter™ is no different. Its first order of business is to scan the LPN or identification barcode. Unique identification is required when manifesting a carton for a carrier. This can be the specific order number or a number that is uniquely associated with the order. The Sprinter™ is capable of scanning a wide variety of barcode symbologies, sizes, and locations. Once the barcode is examined, it is now ready to add details. One of the many beneficial aspects of the Sprinter™ is its Allen-Bradley based control system. The open architecture allows the Sprinter™ to expand and integrate with existing and future operations quickly. Additional features such as a dimensioner can speed up operations and provide accurate, error-free details to the carton.

Weighing

The weight of the package is captured and recorded in The Warehouse Control System (WCS) software. The Sprinter™ scale is suitable for weighing parcels up to 75 lbs. and 28” long. With a throughput of 14-18 cartons per minute, the Sprinter™ scale is a viable option to taking your first step into automating the end of line fulfillment process. For faster throughput and additional options, we offer upgraded scales that improve accuracy and processing speed for lighter items or irregular shaped items.

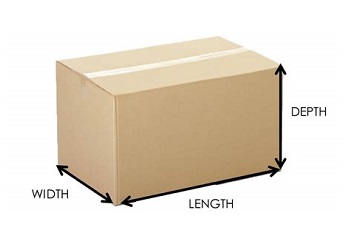

Dimensioning and Cubing

We utilize a laser-based system with an encoder that measures the carton to the nearest 0.25 inches in 3 dimensions. Automating dimensioning can mean significant time & cost savings. On average it takes an employee 15-30 seconds to measure and record the dimensions of a carton. Along with those 15-30 seconds comes mistakes occasionally. Sprinter™’s dimensioner cuts that time down to a fourth and also does it error free as it records the data into the Sprinter™ software. You are now holding your carriers accountable for dimweight charges along with maintaining your service level agreements with customer. Automating dimensional weighing is a valuable option that saves on many fronts. As the leader in dimensional weighing for many years, we have the resources and tools to help you automate your measurement challenges.

Print and Apply Labeling

After all of the data has been captured and recorded it’s time to print and apply the shipping label. The Sprinter software has simple and easy integrations to most major carrier shipping systems, multi-carrier shipping systems, and API’s where we send the address information, parcel information, and order information to process the shipment. Once the label is generated the Sprinter utilizes an all-electric print and apply applicator. It is low maintenance and offers easy label roll change-out. The 14” tamp comes standard with an option for an 22” as an upgrade. For even faster operations we utilize a larger printer applicator with the capacity to hold 3,800 labels per roll with a 36” tamp stroke.

Verify, Sort, Divert

After all of the pieces of the puzzle come together they are checked one last time to make sure they are correct, accuracy is the Sprinter™’s specialty. The Sprinter™ scans the LPN (License Plate Number) and shipping label for a verification of parity check. If all checks out the carton is sent down its proper carrier lane or other sortation method. If there is a problem with the parcel it will be sent down the “jackpot” lane diverted for review by an employee.