Dimensional Weighing

Static Package System 3D

The SPS 3D dimensioning scale is the fastest solution for calculating NTEP Certified dimensions of boxes, flats, polybags, tubes and other irregular-shaped packages. SPS 3D is designed to ensure freight compliance and deter revenue-loss from miscalculated dimensions in retail, office and shipping environments. With an operator display directly attached and no PC interface required, SPS 3D is truly plug and play — simply open, assemble and display dimensions. Instantly. The SPS-3D includes an open-web service API for communication to and from the device for standard line of business software. Many interfaces have already been written and tested including to UPS WorldShip, BluJay Software ClipperShip, and FedEx Ship Manager. The SPS-3D can also be used above automated conveyors, or gravity conveyor systems. Drop-in conveyor kits are also available for scale systems to place the scale and dimensioning scanner in-line with your packing and shipping applications.

Static Package System 3D Features

Measure Irregular Shaped Parcels and Packages

The SPS-3D scanner’s multiple patented innovative sensing technologies and 3D imaging, work together to optimize time and throughput for boxes, flats, polybags, tubes and irregular shaped packages. While competitive products that ultra-sonic technology are more affordable, they just can’t touch the capability of imaging systems for odd shaped items. For flats or packages under 1.2 inches, use the flat detection trigger located on the base plate or connect to a compatible scale.

Scale and Indicator Options

Interfaces are available for a wide variety of NTEP Certified shipping scales and indicators to the SPS-3D using the USB connection. Unlimited scale possibilities are available when using the integrated API with a custom user interface like Bluetooth, RS232, TCP/IP, and more. We offer scales from Rice Lake, Mettler Toledo, NCI – Weigh-Tronix, and more. Contact us to see if your existing scale will work with the SPS-3D today.

NTEP Certification

If your organization is using dimensions and weights captured at the time of sale, then you need a NTEP certified dimensioning system and scale; OIML certification in Europe. NTEP certified dimensions for parcels on the SPS-3D are calculated in 0.2 seconds, to 0.2 inches of accuracy. Irregular shapes are calculated to 0.5 inches of accuracy when operating in NTEP mode. The SPS 3-D can also be run outside of NTEP mode for extremely small items and granular detail.

Open Web Service API

The SPS-3D can collect dimension and weight data, along with a unique ID and save in a .csv file that can be imported into the customer’s WMS or ERP system. No additional software is required. Most customers will choose to connect to the web service API through their line of business software like ORACLE, SAP, and Microsoft Dynamics GP. The API is started automatically when the device is turned on.

Run With-Out Software

Plug and play. The SPS-3D has an operator display directly attached to the device and no PC interface or software is required to operate. Instantly capture dimensions and weights by opening the box and assembling in a few minutes; just connect to a power source.

Capture Dimensions Over Almost Any Surface

The unique technology developed for the SPS-3D allows you to implement in existing shipping and receiving applications. The dimensioning scanner can be placed above existing counters, desktops, scales, and even conveyors. Because of the camera technology shiny and glossy surfaces like stainless steel will need to be avoided, but you can rely on our team of experts to test your application thoroughly. If you are utilizing an existing gravity conveyor, we also offer a drop-in conveyor kit for the Mettler Toledo BC series of scales to fit with-in your environment.

Dimensional Scanning Data Collection Interface

Further automate capturing dimensions and weights by incorporating data collection devices like handheld scanners and mobile computers. Using the API, you can capture SKU’s, and other important material handling information. This information can be automatically entered into your existing WMS, TMS, or ERP system. With the web services interface the dimension and weight data can be displayed with-in your existing software interface or terminal emulation application.

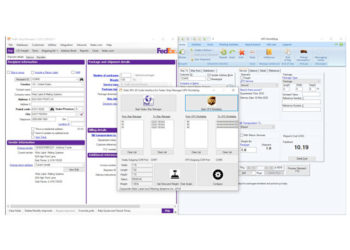

UPS World Ship and FedEx Ship Manager Interface

The SPS-3D comes with a standard UPS WorldShip interface that automatically populates the weight and dimensional data into the carrier’s shipping system. We have developed a unique FedEx Ship Manager interface that accomplishes the same goal, but also allows you to run at the same time as UPS World Ship. Most other interfaces available require you to run only one carrier application at a time to collect dimensional and weight data.

Label Printer Integration

During the data collection process using the SPS-3D dimensional weighing system, you can also integrate with many makes and models of thermal label printers to print product details including weight, length, width, and height. These labels can be used later in your material handling process to capture dimensions and weights using barcode scanners, or to trigger business decisions made by staff members.