Dimensional Weighing

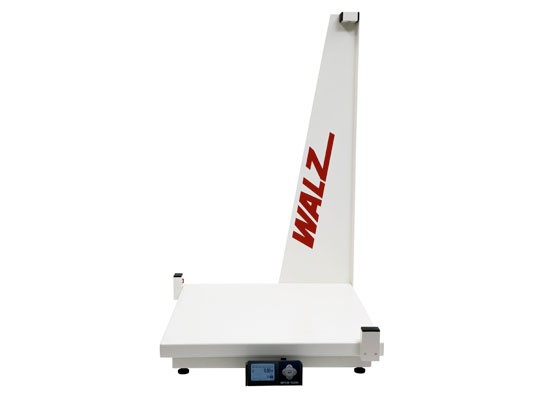

Static Package System MT

Customers with existing Mettler Toledo PS60 and BC60 shipping scales that don’t want to purchase another shipping scale, can add the SPS MT dimensional weighing platform to their current scale. The SPS MT has all of the same standard features as the SPS, combining affordable pricing with high-tech dimensioning. Designed for accurate, reliable and efficient capturing of shipment and product data, dimensions, weight, dimensional weight and up to 10 custom data fields. The SPS MT’s measuring performance is on par with market leaders but at a fraction of the cost. The SPS line of dimensional systems is quickly becoming the market leader across the globe. The standard size SPS can measure up to 24” x 24” x 37” objects.

Static Package System MT Features

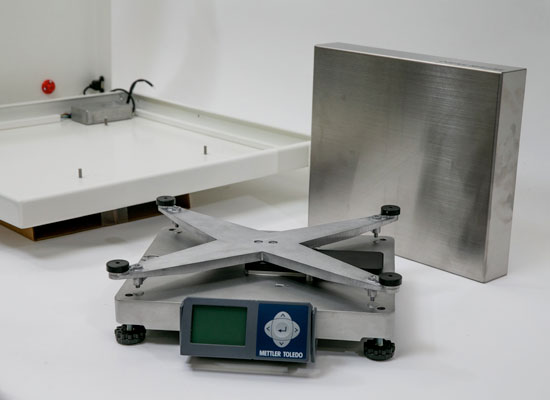

Use Your Existing Mettler Toledo Shipping Scale

The SPS MT dimensional scanning and weighing system incorporates your existing precision industrial grade Mettler Toledo PS60 or BC60 scale system that delivers high accuracy weights for every package. Each system utilizes Mettler Toledo’s NTEP Approved scales to ensure high accuracy dimension weight. Trust the market leaders in weighing and dimensioning technology.

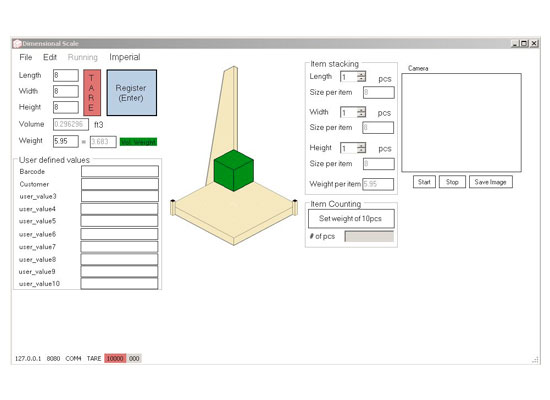

Advanced Interface Application

The SPS dimensional scanning system includes, at no additional cost, advanced operational software designed to run on most any standard windows device. This integrated software application provides users with a very intuitive, flexible capabilities for interfacing to existing shipping and warehousing systems. Your team can now easily operate and interface your dimensional and weight data directly into your existing software platforms. Thorough testing has been completed with USPS/FedEx/DHL/USPS software applications and interfaces, as well as many WMS and ERP systems like Oracle, SAP, and Microsoft.

Ultra-Sonic Sensors For Accurate Dimensional Scanning

The SPS System incorporates industrial grade ultra-sonic sensors that produce accurate dimensional measurements for many different packages. Unlike some dimensional weighing and cubing systems, the advanced system is designed to allow for reliable and accurate operation in rough industrial and shipping station applications. The ultra-sonic sensors are not affected by direct and in-direct lighting that can affect other camera based systems like our SPS 3D.

Dimensional Scanning Data Collection Interface

Further automate capturing dimensions and weights by incorporating data collection devices like handheld scanners and mobile computers. Using the ten custom fields in the SPS software, you can capture SKU’s, and other important material handling information. This information can then be imported via .csv, or using the web services interface can be automatically entered into your existing WMS, TMS, or ERP system. With the web services interface the dimension and weight data can be displayed with-in your existing software interface or terminal emulation application.

Camera Interface

Add a high definition camera to your SPS dimensional weighing and scanning system to capture and store image files for every object. Using a standard USB web cam, the SPS software will capture an image and save it along with all of the user text fields. You can choose the storage location for images, and the custom user field that you would like to use for the name; like SKU or item number. This feature is beneficial in pack stations where users want to verify contents, or for receiving application in order to capture product images for WMS applications.

No On-Site Maintenance Or Calibration Required

The SPS dimensional weighing scanner does not require expensive on-site maintenance or calibration. All essential services can be done through remote access support, with-out requiring a Walz Label and Mailing Systems technician to be on-site. This feature combined with affordable replacement parts makes the SPS one of the most cost effective systems to implement. If you require annual or quarterly calibrations, Walz Scale can provide weight kits, or we can get you in contact with a local scale dealer in your geographic location.

Label Printer Integration

During the data collection process using the SPS or SPS-XL dimensional weighing system, you can also integrate with many makes and models of thermal label printers to print product details including weight, length, width, and height. These labels can be used later in your material handling process to capture dimensions and weights using barcode scanners, or to trigger business decisions made by staff members.